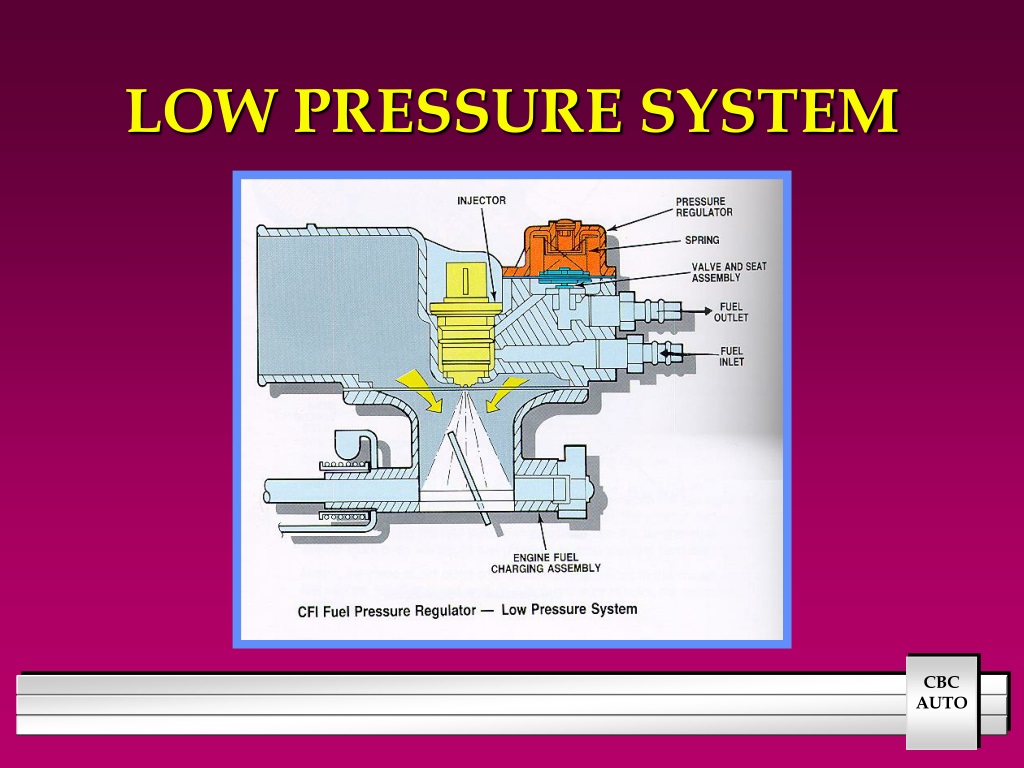

Thus, the phase of the pump camshaft relative to the engineĬrankshaft controls the start of injection, while the force givenīy the initial displacement of the spring gives the opening Surface, overcomes the spring force and opens the valve. Pressure in the injector volume, acting on parts of the needle

Injection needle keeps the injection valve closed until the Through which the fuel sprays into the cylinder. The fuel trapped above the plunger is forced through a check valve Traditional injection system An auxiliary cam on the engineĬamshaft drives a single-cylinder injection pump.Įarly in the stroke of the plunger, the inlet port is closed and This technique allows fuel to be injected as needed, saving fuel Words, compression and injection occur independently of each other. (ECU) modifies injection pressure precisely and as needed, based onĭata obtained from sensors on the cam and crankshafts. The engine's electronic timing regulates injection pressureĪccording to engine speed and load. Remains permanently available throughout the fuel line. Pressure regardless of the injection sequence. Have to build up pressure anew for each and every injectionĬycle, the new common rail (line) engines maintain constant The Technology Whereas ordinary diesel direct fuel-injection Is much more difficult and costly to achieve. Multiple injection events are possible with these older systems, it That could be commanded during a single combustion event. They were limited in the number and timing of injection events Single pumping event with no accumulator, and thus the relationship Injection pressure is tied to the instantaneous pressure of a Rail systems with the unit or distributor systems, however, the This relationship is true with all pumps, even those used on common This typically meant that the highest injection pressureĬould only be achieved at the highest engine speed and the maximumĪchievable injection pressure decreased as engine speed decreased. Injection pressure was proportional to engine Instead of supplying separate piston pumps for fuel supply, theĬommon rail alone supplies high pressure fuel to eachcylinder.ĭisadvantages of Diesel Engine They were cam driven, and Our product offerings include millions of PowerPoint templates, diagrams, animated 3D characters and more.What is CRDi? CRDi stands for Common Rail Direct injectionĭirect injection of fuel into cylinders of an engine viaĪsingle, common line, called common rail which isconnected to all is brought to you by CrystalGraphics, the award-winning developer and market-leading publisher of rich-media enhancement products for presentations. Then you can share it with your target audience as well as ’s millions of monthly visitors. We’ll convert it to an HTML5 slideshow that includes all the media types you’ve already added: audio, video, music, pictures, animations and transition effects.

You might even have a presentation you’d like to share with others.

Fuel injection system ppt free#

And, best of all, it is completely free and easy to use. Whatever your area of interest, here you’ll be able to find and view presentations you’ll love and possibly download. It has millions of presentations already uploaded and available with 1,000s more being uploaded by its users every day. is a leading presentation sharing website.

0 kommentar(er)

0 kommentar(er)